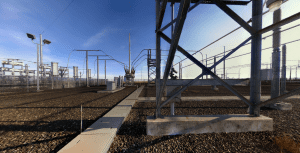

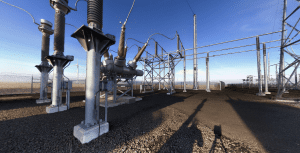

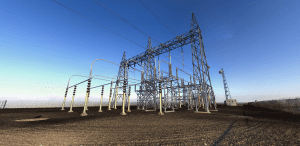

Accurate facility ratings are crucial to the safety and reliability of the electrical grid, as they help in assessing the capacity and performance of substation equipment. To support our client in meeting compliance requirements for facility ratings, our team measured the diameter of the bus pipes and jumpers at specific locations inside each substation bay. To address compliance issues, DJ&A performed a comprehensive scanning survey for multiple substations across our client’s multi-state service area.

Key Services Provided

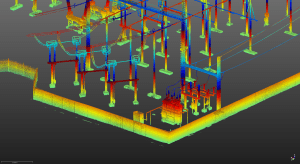

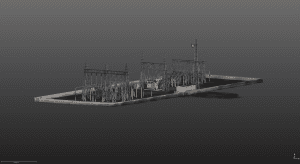

- Conducted field scans of substation yards using Trimble terrestrial 3D laser scanning systems

- Post-processed control and scan data

- Modeled and populated the diameters of the points of interest of the substation bus piping and jumpers, from structures over a hundred feet tall to jumpers less than a half inch in width

- Performed all surveying tasks in accordance with client manuals, bulletins, and relevant statutes and regulations

- Utilized existing forms, templates, research documents, and materials such as aluminum cap monuments, rods, posts, and field note forms

- Maintained the highest safety standards in the high-voltage substation environments: conducted tail-gate safety meetings per project visit, verified fire danger daily, complied with Arc-Flash PPE requirements, coordinated substation entry permits and took necessary precautions to avoid hazards

Value Added

DJ&A’s substation scans provide clients with an existing conditions point cloud that can be integrated into a GIS system. This allows the client to analyze the current structural make-up of the substation and help with any scheduling of routine maintenance or compliance work that may be required due to updated regulations. This analysis can take place in a virtual team meeting with team members spread out across offices and regions with no site visit to each substation required every time routine maintenance is needed, or an expansion project is planned.